Next Level Laundry

Kannegiesser at Texcare International 2024

If you do not see the video, please accept all cookies!

Kannegiesser Forum

Every Day 6 - 9 Nov @ The Kannegiesser Booth (D02)

The Kannegiesser booth at Texcare International 2024 will feature a dedicated Forum, where visitors can attend daily presentations showcasing the latest innovations and how Kannegiesser plans to create the "next level laundry" together with its partners of the textile service industry. Presentations will also cover service and myKannegiesser, the online customer portal that includes an online spare parts shop, providing a hands-on overview of this crucial tool. Visitors will have the opportunity to engage directly with Kannegiesser experts, ask questions and gain deeper insights.

Let's create your Next Level Laundry

English: 09:45 - 10:15 AM

German: 10:30 - 11:00 AM

Let's create your Next Level Laundry

English: 01:30 - 02:00 PM

German: 02:15 - 02:45 PM

myKannegiesser

English: 04:30 - 05:00 PM

German: 05:15 - 05:45 PM

Facing staff shortages, rising costs, and growing market demands, laundries are actively seeking effective solutions to address both current and future challenges. Under the slogan "Let’s Create Your Next Level Laundry," Kannegiesser is set to showcase its latest innovations in automation, robotics, ergonomic workstations, sustainable processes, and intelligent logistics at Texcare International 2024. Kannegiesser invites customers to work together to design tailored solutions that transform these challenges into opportunities, elevating laundry operations to the next level.

"The laundry industry is at a critical juncture where the need for efficiency, sustainability, and quality is more pressing than ever," says Tina Kannegiesser, CEO of Kannegiesser. "Our focus at Texcare is on delivering the next level of technology and services that enable our customers to navigate these challenges successfully." Michael Harre, Chief Sales and Service Officer, adds: "We are committed to developing tailor-made solutions that not only meet the current demands of the market but also future-proof our customers' businesses. The innovations we present at Texcare will highlight this commitment."

Next Level Automation

In response to the growing demand for automation as a solution to staff shortages and the need for more efficient production, Kannegiesser is introducing new solutions in robotics and software.

Among the highlights is the AutomaticDry Work Line including the feeding robot Robofeed RFT and the Speedline folding machine for dry work processing. This system automatically feeds, folds, sorts, and stacks mixed batches of towels from hotels and hospitals. Utilizing advanced camera technology combined with Kannegiesser’s ServoTronic, the system efficiently separates and feeds each item into the folding machine, processing over 600 pieces per hour at maximum speed.

Kannegiesser's SmartLaundry eXperience introduces a range of innovative solutions designed to automate, optimize and streamline laundry operations.

SmartVue is a graphical interface that allows laundries to visualize their entire operation on a virtual map. Operators can zoom in on specific machines, check performance, and even track the location of specific customer laundry batches in real-time.

In addition, BatchPrinting and Pack&Label provide hands-on solutions to streamline operations even for smaller scale laundries. BatchPrinting enables automatic and therefore reliable program selection even when using laundry carts. By printing machine readable tickets after dryer unloading, laundries can establish a seamless flow of information from the washing through the finishing area. Operators can scan the barcode information on the ticket at the ironer line or dry work folding machine, immediately retrieving the correct processing program. In shipping, Pack&Label is the reliable solution for complete and fast commissioning. Laundry carts are marked for dispatch using automatically generated packing lists displaying article quantities for each customer.

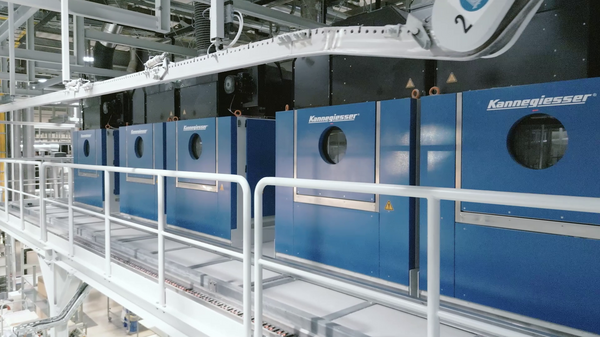

For laundry logistics, the Kannegiesser monorail system with eVueControl offers a seamless, automated linen transport solution that is easy to install yet extremely reliable in operation.

Next Level Sorting

Sorting is a critical process in every laundry, and Kannegiesser is setting new standards with its latest innovations. Kannegiesser’s sorting solutions are just as diverse as the laundries they serve, offering a variety of systems tailored to different stages of the laundry operation process. From the soiled side to the clean side, and even within the machine, these solutions can identify and sort articles by measurements, color, barcode and RFID technology to meet the specific needs of each laundry.

The introduction of Kannegiesser’s automatic sorting system for soiled garments marks a significant leap forward in laundry automation. This system uses RFID chips embedded in garments to identify and sort items automatically into laundry carts or bags. Additionally, it has the unique capability to detect foreign objects in garments through X-ray technology, even in thick industrial clothing, preventing damage to machines and ensuring the safety of workers.

Another revolution in sorting capability marks the SFM-E folding machine for flat linen. It automatically sorts and stacks up to six different types of items such as sheets and tablecloths in both single and double-lane operation. The SFM-E achieves up to 1,800 parts per hour in single-lane operation and up to 2,000 parts in double-lane operation, making it an ideal solution for laundries dealing with a wide variety of textiles.

In garment logistics, Kannegiesser presents the TLL system, which automates the process of pairing garments with hangers inside a small tunnel using RFID technology. Unlike other solutions, the TLL significantly accelerates the identification process, ensuring garments are identified faster and more reliably than ever before. Workers won’t have to pair the item with the hanger during the loading process anymore. This not only simplifies the workflow but also enhances efficiency and accuracy in garment processing.

Next Level Ergonomics

Ergonomics is a key focus in Kannegiesser's vision for the modern laundry, with innovations designed to reduce physical strain on workers while boosting productivity.

The EMR SynchroPro Remote feeding machine is a standout example, offering a 37.5% increase in feeding capacity and significantly reducing the physical strain on operators. The automatic item lift allows workers to easily handle large and heavy items, improving both productivity and workplace safety.

Similarly, the EMH ErgoSpeed is designed to process up to 1,800 sheets per hour with minimal operator effort. The machine's ergonomic design, including adjustable input panels and a feeding station height that keeps arms below heart level, ensures operators can work comfortably and efficiently.

For garment processing, the X-Loader offers the perfect blend of productivity and ergonomic design. Its height-adjustable feed station and intuitive controls make it easy to operate, ensuring that workers can maintain high productivity levels with minimal physical strain.

Next Level Quality

High-quality results are essential in the textile service industry, where customers expect nothing less than flawless linens and garments. Kannegiesser’s innovations are designed to ensure that laundries consistently deliver on these expectations. This means producing accurately stacked linen, free from stains, marks, or holes, with a smooth finish and reliably clean washing every time.

In washing, the PowerTrans Vario batch washer delivers unparalleled washing results thanks to its ActiveDrop technology, which provides excellent washing mechanics while being gentle on fabrics. It works deep into the fibers, allowing wash performance, textile care and a guarantee of hygiene as never before seen or felt.

The SynchroPro feeding machine elevates linen feeding to the next level, combining dynamics, precision, and reliability through its advanced SwiftCare system. It redefines how textiles are handled by ensuring the leading edge enters the ironer line with perfect alignment. This is achieved through a swiveling transfer bar that swiftly picks up each item, gently lays it down without overspreading and secures it with a strong vacuum—eliminating the need for a clamping bar. The result is reliably impeccable leading edge quality ensuring perfect ironing and folding quality.

Quantex further enhances quality control by automatically detecting stains, holes, and irregularities in textiles, ensuring that only flawless items reach the end customer.

In garment folding, the FA-X series provides solutions with both manual and automatic feeding, offering flexibility and precision in handling garments. The system’s advanced sensor technology ensures that each item is folded according to its specific requirements, delivering consistent, high-quality results.

Next Level Sustainability

Sustainability is not just a trend; it’s a necessity for modern laundries. Kannegiesser's innovations in this area are designed to reduce energy and water consumption, ultimately leading to cost savings and a smaller environmental footprint.

The XStream tunnel finisher is a prime example of this commitment to sustainability. With its newly designed counterflow concept, the Xstream achieves the same efficiency with three modules as a standard tunnel finisher does with four, saving time, energy and space.

The innovative process control Eco2Power combines lowest energy consumption with maximum performance, securing a low energy consumption of 1.1 kWh/ltr evaporated water, while shortening overall process times. This system makes the PowerDry the most efficient transfer dryer on the market. In ironing, Kannegiesser’s HPM ironer with heating band technology delivers high performance with significantly reduced energy consumption, making it the most energy-efficient ironing solution available.

As the largest exhibitor at Texcare International 2024, Kannegiesser invites textile service providers and everyone interested to explore these innovations firsthand. “By embracing the latest technology, our partners of the textile service industry can not only tackle current challenges but also pave the way for future success,” says Tina Kannegiesser. “We are excited to demonstrate how our solutions can elevate laundry operations to the next level.”