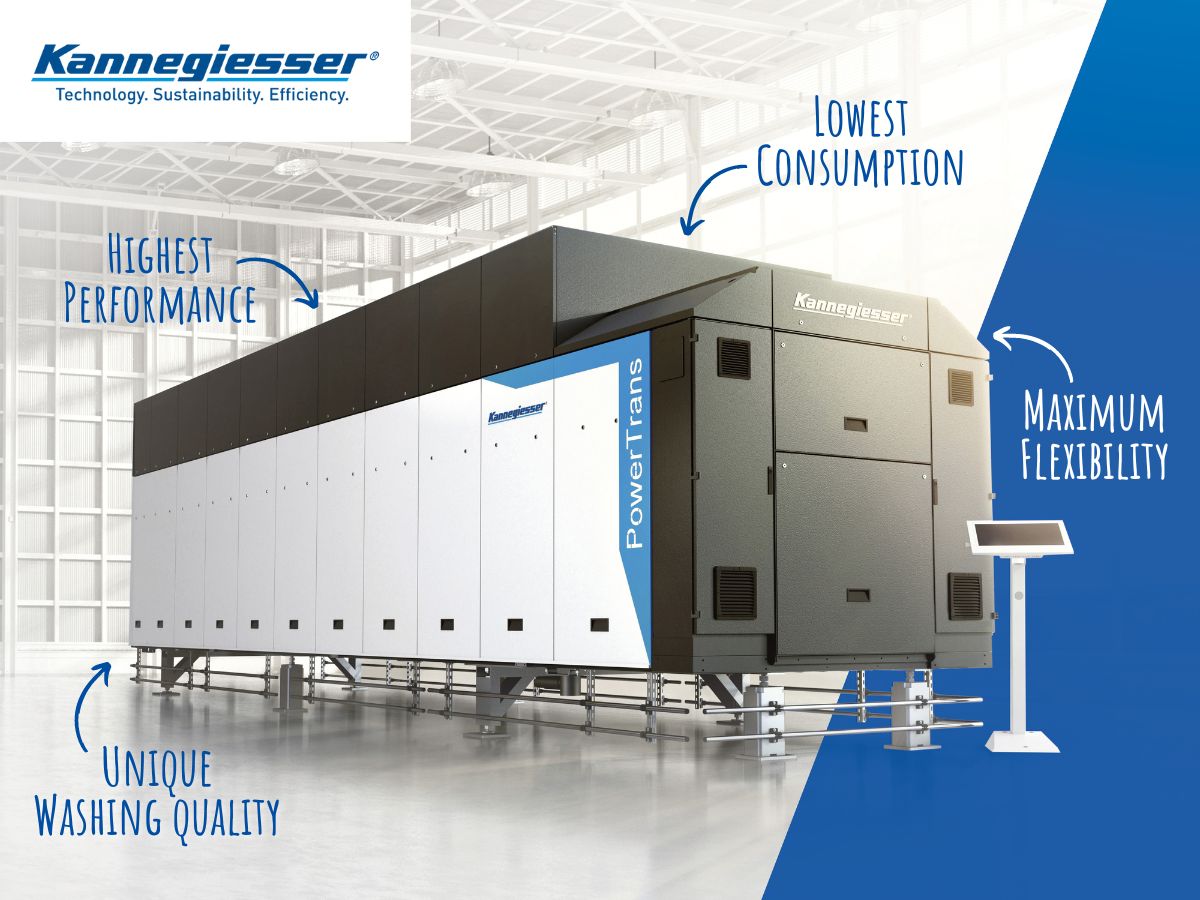

Our heart beats for the continuous improvement of your laundry processes. The PowerTrans has been continuously developed over 25 years and is now at the top of industrial washing technology. It delivers outstanding washing quality and hygiene, masters logistical challenges on a daily basis, is a reliable guarantee of performance and at the same time moderate in its consumption of resources.

The quality of the wash results is unique.

The laundry lives from delivering high quality products every day. This is the only way it can get satisfied customers and build long-term customer relationships. The laundry customer sees and feels the quality of the goods washed on the PT Vario in the form of excellent cleanliness, safe hygiene and the best possible textile protection.

No batch washer offers more flexibility.

The truck is late? A certain batch needs to be processed in advance at short notice? The everyday life of a laundry is anything but straightforward! Adherence to deadlines and tight time slots with ever-increasing traffic volumes often demand a high level of flexibility from employees and machine technology. The PowerTrans Vario offers application possibilities that can otherwise only be achieved with washer extractors.

Highest performance with capacity reserves.

Anyone who chooses a PowerTrans Vario today will receive a batch washer with the largest output within the smallest possible space. When laundry volumes increase or there are temporary peak loads, your customers can rely on the PowerTrans Vario as a workhorse and a guarantee of performance.

The batch washer with the lowest consumption.

Resources are becoming scarcer and therefore more and more expensive. Continuous efficiency improvements are necessary to cushion these cost increases. The PowerTrans Vario minimizes water and energy consumption and thus generates a lasting cost advantage in the long term. In addition, the laundry's CO2 emissions are reduced, which is a major plus for sustainability reporting to customers and business partners.

And how does the PowerTrans Vario make all this possible?

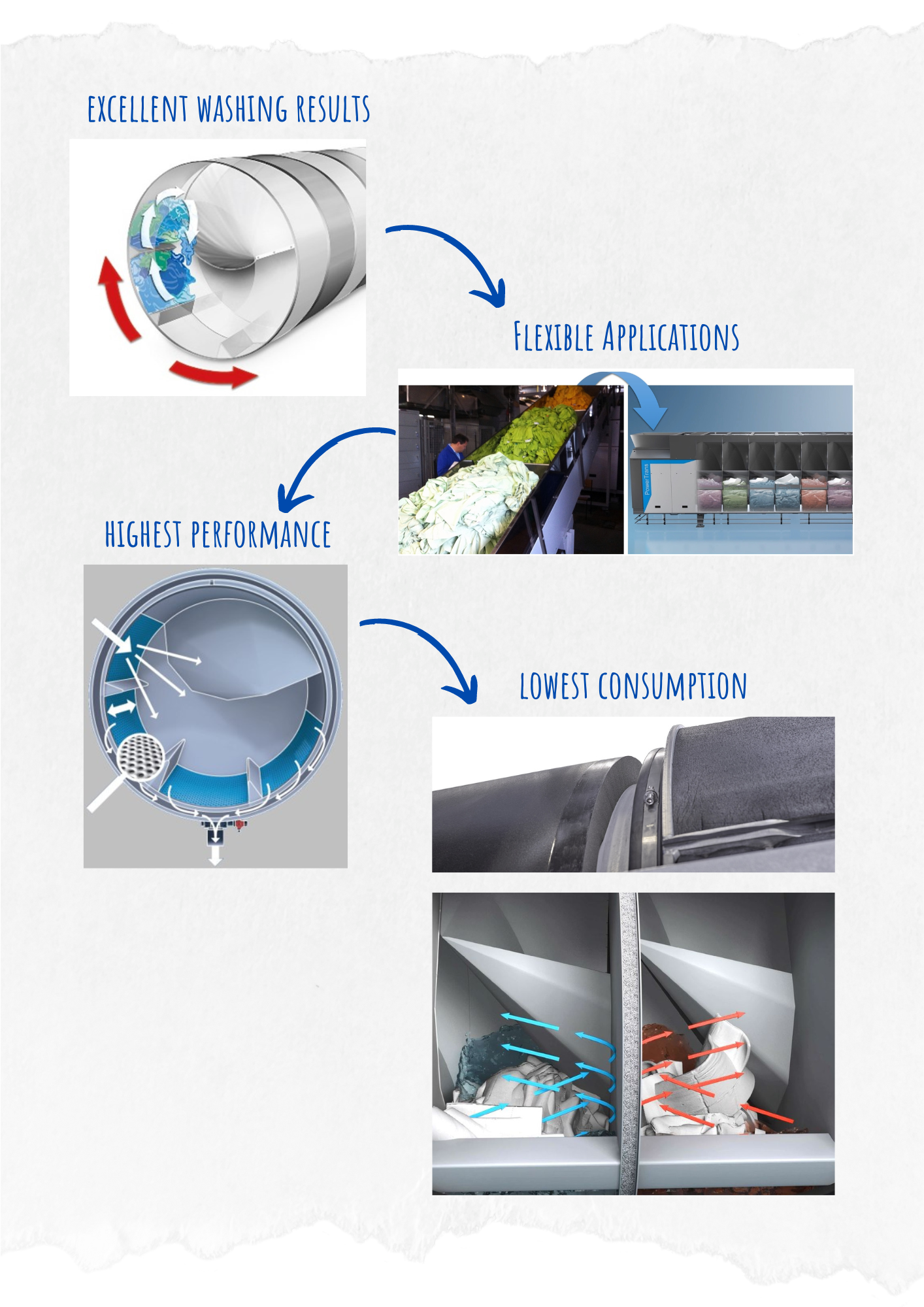

- Excellent washing results

If we talk about the quality of washing results, we then talk about the ActiveDrop wash action! By "lifting, throwing, compressing and flow-through" the dirt is removed from deep within the fibers, and at the same time harmful friction on the textile surface is avoided. Strict standing baths ensure that each batch is washed with exactly the liquor and chemicals that it required according to the wash program and current load quantity. There is no mixing between neighboring batches.

- Flexible applications

The "Standing bath principle" is also the basis for the flexibility of the PowerTrans Vario! Unlike other batch washers, washing sequence and lot size are determined by current needs, not by technological limitations of the machine. With the "Washing without empty chambers" function, even output losses due to empty compartments when changing colors are a thing of the past.

- Highest performance

No empty compartments when changing colors, plus high overload safety thanks to the drum design with straight drum walls and large transport chute: This leads to the highest possible performance of the PowerTrans Vario under all operating conditions. The active washing time is optimized, the non-productive times are minimized – for example through the fast processes in the QuickExchange chamber and through the short transfer time due to intelligent signal exchange with the extraction press or centrifuge.

- Lowest consumption

With "ActiveDrop" you can also explain the low consumption of the PowerTrans Vario: Thanks to the optimized mechanical action, the washing result is less dependent on temperature, time and chemistry according to the Sinner Circle. In addition, many details of the PowerTrans Vario are designed to save energy. Examples of this are the main wash area with 60 mm full foam insulation and thermo walls to the pre-wash and rinse chambers, the fully insulated recovery tanks and the innovative steam nozzles without the addition of compressed air.